Description

Key Points:

- Rubber wedges are produced via vulcanization at 150 °C using the flame-retardant ONB-1/09 rubber mixture, with post-production visual inspections to ensure quality.

- They are primarily used in railway transport to secure stationary wagons, especially those carrying hazardous materials, in fire- or explosion-prone areas, but not for stopping moving wagons.

- Technical requirements include specific standards for hardness, strength, flame retardancy, and other properties to guarantee safety and performance.

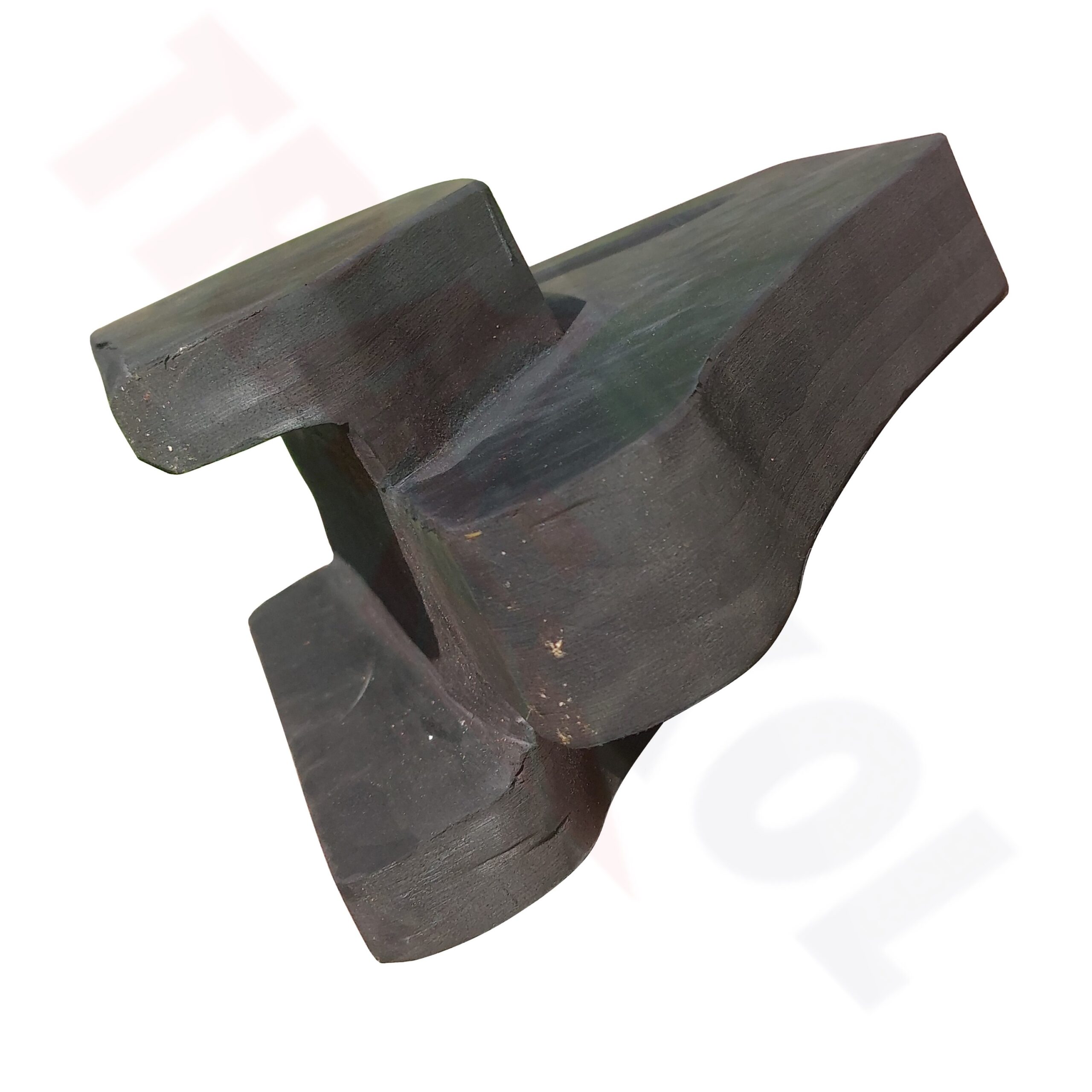

Manufacturing Process The wedges are manufactured using the vulcanization method at a temperature of 150 °C. The flame-retardant rubber mixture ONB-1/09 is used for the production of the wedges. After manufacturing, each wedge is subjected to inspection through visual examination, aimed at detecting any imperfections and vulcanization defects. Rubber flashes are removed, and the edges are rounded.

Application Rubber wedges are used in railway transport to immobilize stationary wagons in locations where there is a risk of fire or explosion. The wedges have particular application in immobilizing railway tank wagons used for the transport of hazardous materials. The wedges cannot be used to stop wagons that are in motion.

Required Technical Parameters:

| Lp | Parameter | Norma | Wymagania |

|---|---|---|---|

| 1 | Twardość [°ShA] | PN-EN ISO 868:2005 | 70 ±5 |

| 2 | Wytrzymałość na zarwanie [MPа] | PN-ISO 37: 2007 | ≥ 15,0 |

| 3 | Wydłużenie przy zerwaniu [%] | PN-ISO 37: 2007 | ≥350 |

| 4 | Trudnopalność: | PN-C-05013:1993 | |

| – średni czas palenia się i żarzenia 6 -ciu próbek [s] | ≤5,0 | ||

| – średni czas palenia się i żarzenia jednej próbki [s] | ≤15,0 | ||

| 5 | Czas podwulkanizacji [min] | PN-ISO 6502:2007 | ≤5,0 |

| 6 | Odporność na ścieranie [cm³] | PN-ISO 4649:2007 | <0,200 |

| 7 | Rezystancja powierzchniowa [Ω] | PN-EN-61340-2-3:2002 | ≤3×10^9 |

Reviews

There are no reviews yet.